Christian Micallef, Research & Development Engineer and Yuri Zhuk, Technical Director are two of the four authors of the peer-reviewed paper ‘Surface finishing and residual stress improvement of chemical vapour deposited tungsten carbide hard coatings by vibratory polishing’ newly published in Elsevier’s Surface & Coatings Technology.

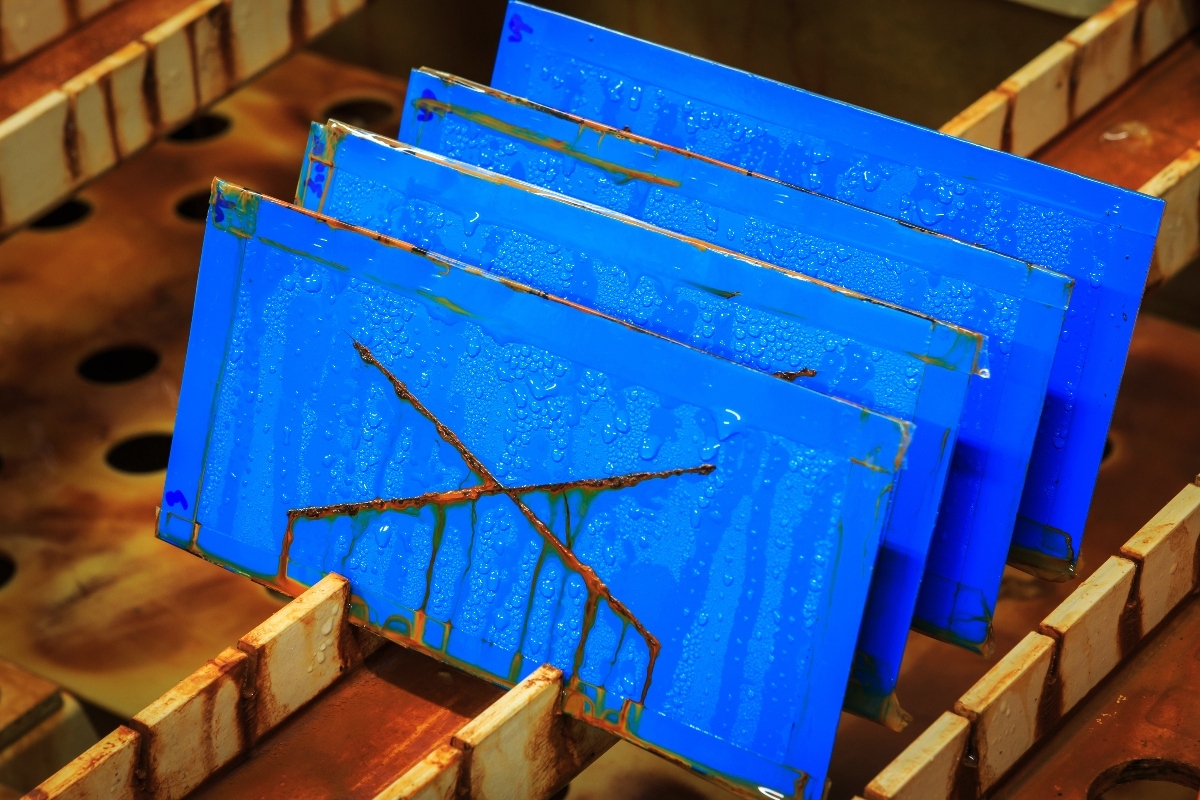

W/WC coatings deposited through CVD have a matt grey texture which requires a post-coating surface finishing action to adhere to surface roughness and geometrical tolerance specifications. As part of the ongoing work to identify new surface finishing techniques, vibratory polishing and its impact on Hardide coatings has been investigated. In this paper, the changes in surface roughness and the evolution of compressive residual stress as a function of time have been studied. The surface finishing mechanisms responsible for the improvement in surface finish have been demonstrated through Atomic Force Microscopy and Scanning Electron Microscopy images. The paper concludes that vibratory polishing is an effective finishing technique on CVD W/WC coatings with a hardness greater than 1300 HV and therefore potentially could be used for processing parts with complex geometries.

The paper can be downloaded from our website here.