Corrosion protection is an essential part of extending the lifespan of metal components used in demanding industries such as aerospace, oil and gas, power generation and advanced manufacturing. Without effective protection, corrosion leads to reduced strength, costly maintenance and premature failure if the proper precautions are not taken.

A wide range of coatings are available, each with distinct advantages and limitations. This article reviews the most common corrosion-resistant coatings, compares their suitability across applications, and explains why CVD coatings represent the most effective long-term solution

Why use corrosion coatings?

Bare metals are rarely able to withstand prolonged exposure to aggressive environments. Even stainless steels and advanced alloys are vulnerable to localised corrosion, erosion or stress-related cracking under the right conditions. Coatings are therefore applied to act as a barrier between the substrate and its environment, and to provide additional performance benefits. Effective corrosion coatings aim to:

- Prevent chemical attack by isolating the base metal from oxygen, chlorides, acids, or other corrosive agents.

- Reduce wear and erosion that accelerate corrosion by removing protective oxide layers.

- Improve reliability in safety-critical components by extending service intervals and reducing failure risk.

- Lower lifecycle costs by cutting down on repairs, replacements and unplanned downtime.

The main coatings compared

Across industry, several coating technologies are commonly used to protect metal components against corrosion. Each brings its own strengths and weaknesses, and understanding these differences is essential when selecting the most effective solution for a given application.

Hard Chrome Plating (HCP)

Hard chrome plating has been a workhorse of industry for decades, valued for its wear resistance and relatively low cost. However, it comes with significant drawbacks with a major one being that it is reliant on the harmful chemical hexavalent chromium.

- Advantages: Good hardness and moderate corrosion resistance, can be applied to many substrates, and an established supply base.

- Limitations: Contains micro-cracks that allow corrosive agents to reach the substrate, has poor performance in aggressive environments, presents significant environmental and health concerns due to hexavalent chromium.

- Applications: Historically common in aerospace actuators, hydraulic parts and automotive components, but increasingly restricted under EU REACH and OSHA regulations.

Thermal spray coatings (HVOF, plasma spray, etc.)

Thermal spray techniques deposit molten or semi-molten particles onto surfaces, creating thick protective layers. High Velocity Oxy-Fuel (HVOF) coatings with WC/Co binders are especially widespread. That said, thermal sprays are a line-of-sight process, meaning internal surfaces and complex geometries cannot be uniformly coated

- Advantages: Can build very thick coatings with good wear and erosion resistance; widely available and cost-effective for large external surfaces.

- Limitations: Cannot coat complex geometries, sprayed surfaces are rough and require post-grinding, porosity and binder degradation reduce corrosion protection, “cheese-grater” effect on seals due to roughness.

- Applications: Oil and gas tools, aerospace landing gear, turbine blades, pumps and valves.

Physical Vapour Deposition (PVD)

PVD coatings provide very thin, extremely hard layers that are effective for precision components. Deposited using line-of-sight vacuum processes, these coatings typically measure less than 5 microns in thickness, offering high hardness and low friction but limited load-bearing capacity.

- Advantages: High hardness, smooth surface finish, good wear resistance, suitable for precision applications.

- Limitations: Prone to cracking or spalling under impact, line-of-sight process unsuitable for complex internals, less effective in aggressive chemical environments due to thinness and potential pinholes.

- Applications: Cutting tools, decorative coatings, optical and electronic components.

Electroplated zinc and other sacrificial coatings

Zinc and similar galvanic coatings are widely used to protect steel through sacrificial action. When exposed to a corrosive environment, the zinc layer corrodes preferentially, effectively shielding the underlying steel until the coating is consumed. This mechanism provides reliable short- to medium-term protection, particularly in environments where moisture and oxygen are present.

- Advantages: Low cost, simple application, sacrificial protection for steel.

- Limitations: Limited lifespan in aggressive environments; unsuitable for high-performance aerospace or oil and gas components.

- Applications: Construction, automotive and general engineering.

Chemical Vapour Deposition (CVD) - the gold standard

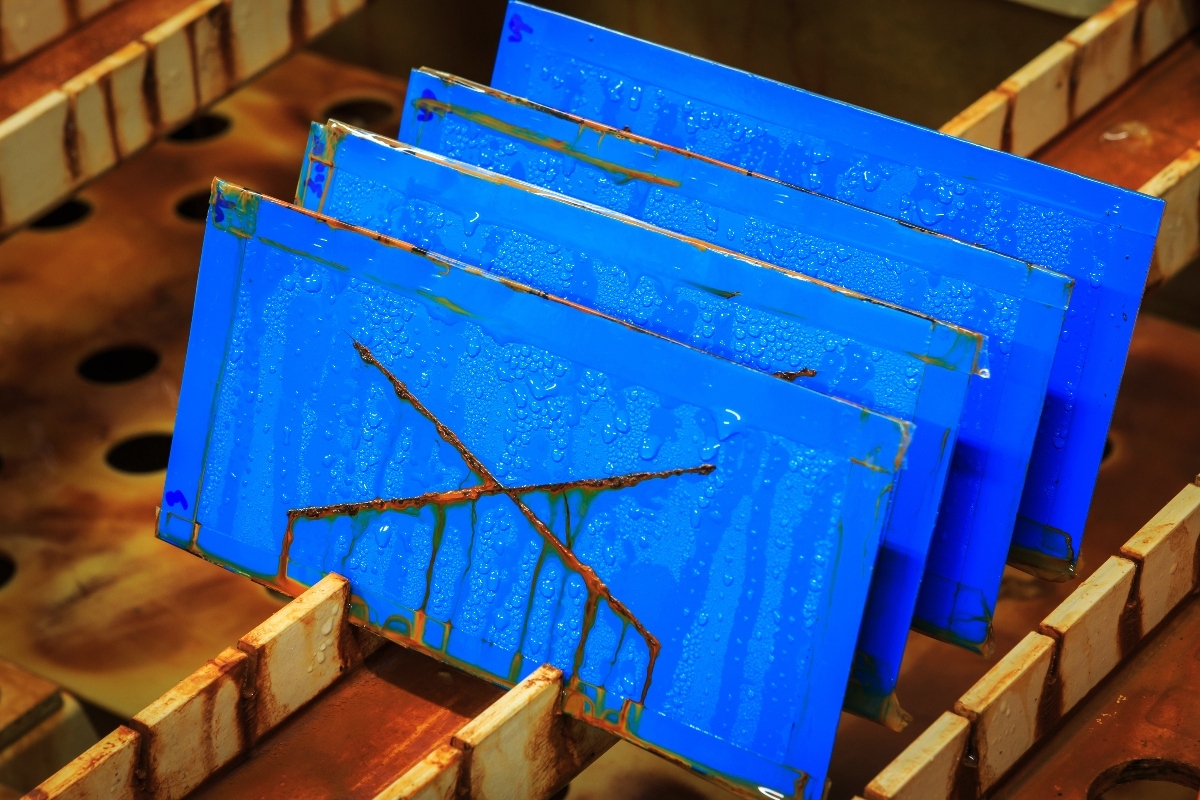

Nanostructured tungsten/tungsten carbide CVD coatings represent a new generation of protective technology. Deposited atom-by-atom from the gas phase, they create a dense, pore-free barrier metallurgically bonded to the substrate. This provides a uniform corrosion resistant layer around complex geometries, making it the perfect candidate for a wide range of components.

Advantages:- Pore-free structure eliminates corrosion pathways.

- Uniform deposition on complex geometries, internal surfaces and non-line-of-sight areas.

- High hardness (up to 1600 Hv) with exceptional toughness and impact resistance.

- Superior chemical resistance to acids, H₂S and aggressive fluids.

- Environmentally safe and fully REACH compliant.

Applications:

- Applies across industries. Aerospace actuators and turbine parts, oil and gas downhole tools, pumps, valves, power generation components and advanced manufacturing tooling.

The best coating for complex geometry components facing corrosion

Corrosion takes many forms from gradual uniform attack to localised mechanisms like pitting, crevice corrosion and stress corrosion cracking. Each reduces component life and reliability, often leading to costly and unexpected failures.

Traditional coatings can leave weaknesses, but Hardide CVD tungsten carbide coatings provide a dense, pore-free barrier that protects against uniform, localised and stress-driven corrosion even on complex geometries.

For a deeper understanding of these mechanisms and how to prevent them, download our Engineer’s Guide to Corrosion below.