Electrolytic alkaline cleaning is a specialised surface treatment process designed to remove contaminants from metal components using an electrically charged alkaline solution. It’s one of the most effective methods for achieving complete surface cleanliness even on components with intricate geometries, deep recesses or non-line-of-sight areas where traditional cleaning techniques can struggle.

The process is vital in industries where precision coatings or bonding rely on absolute surface integrity. All in all, electrolytic alkaline cleaning ensures that parts are chemically free of the oils, greases and residues that can compromise downstream performance.

How electrolytic alkaline cleaning works

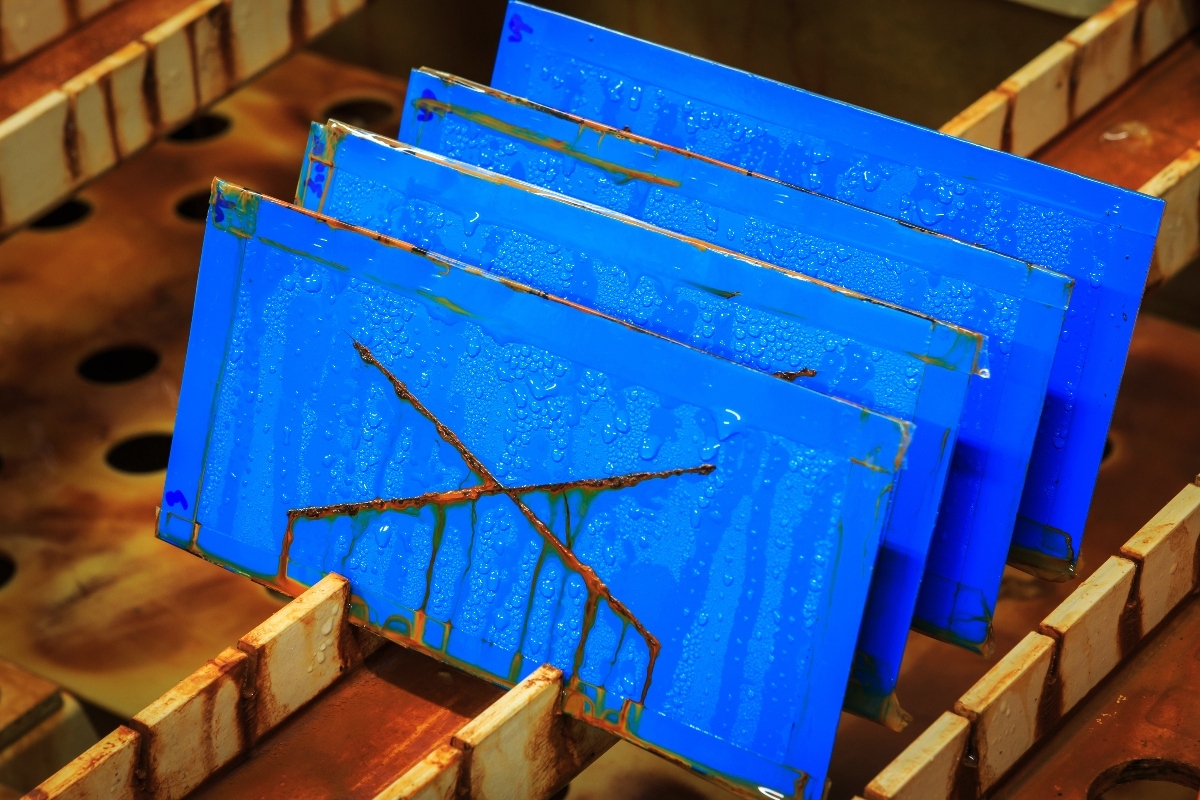

At its core, the process combines two cleaning forces of chemical action and electrochemical activity. Components are immersed in an alkaline cleaning solution containing agents that emulsify and displace organic and inorganic contaminants. When an electric current passes through the bath, it enhances the breakdown of oils and oxides on the component surface.

Depending on the polarity applied, electrolytic alkaline cleaning can operate in anodic, cathodic or dual-polarity modes:

- Anodic cleaning (component as an anode) helps remove metal oxides and fine films.

- Cathodic cleaning (component as a cathode) is more aggressive, breaking down oils and greases effectively.

- Dual-polarity cleaning alternates between the two, combining benefits for a superior finish.

This electrically assisted mechanism means the cleaning action penetrates areas inaccessible to conventional mechanical or spray-based methods like blind holes and internal threads. The end result is a consistently clean surface, perfectly prepared for further surface treatments or coatings.

The value of electrolytic alkaline cleaning

For many engineered components and their coatings, the cleaning stage is an essential step. Contamination left behind on metal surfaces can significantly reduce coating adhesion and compromise the protective nature of the coating in various environments. Electrolytic alkaline cleaning offers several key advantages in this area.

- Superior contaminant removal: Effectively breaks down and disperses oils, greases, oxides and particulate residues.

- Uniform cleaning of complex geometries: Ensures consistent cleanliness across internal and external surfaces.

- Enhanced coating adhesion: Provides the ideal substrate for subsequent treatments like electroless nickel plating, passivation or advanced coatings.

- Environmentally safer alternatives: Modern alkaline cleaners are often formulated to minimise the use of hazardous chemicals, aligning with sustainability goals.

There are similarities between this method and solvent vapour degreasing. Even though the latter is the most effective method to remove oils and non-water soluble contaminants, it does not remove water-soluble ones such as salts. Electrolytic alkaline cleaning is much more effective to deal with this group of contaminants. So when the solvent vapour and the electrolytic alkaline techniques are both used - this guarantees the best cleanliness by removing both water soluble and non-soluble contaminations.

Integrating electrolytic alkaline cleaning into a precision coating workflow

The true value of electrolytic alkaline cleaning emerges when it forms part of a controlled, multi-stage surface treatment process. In many cases, it serves as the first stage in preparing components for further treatments such as acid passivation, nickel strike plating or chemical vapour deposition (CVD) coatings.

Each subsequent layer or treatment depends on the success of this foundation stage. The cleaner and more chemically stable the base surface, the stronger the adhesion and longer the performance life of the final coating system.

The Hardide advantage: engineered cleanliness for advanced coatings

At Hardide, electrolytic alkaline cleaning is part of a wider suite of precision surface treatments that prepare components for our industry-leading CVD tungsten carbide/tungsten coatings. Our approach is engineered to deliver repeatable, uniform results for complex parts that demand the highest coating integrity.

We use dual-process versatility to tailor cleaning for each component’s geometry and contamination profile. Electrolytic alkaline cleaning penetrates non-line-of-sight areas, while complementary vapour degreasing removes heavy oils and organic residues. Together, these ensure every surface (internal and external) is fully prepared for subsequent treatments or coatings.

This combination of precision surface preparation and world-leading CVD coating technology makes Hardide a trusted partner for industries where reliability, repeatability and performance are non-negotiable.