Vapour degreasing is a precision cleaning method that uses solvent vapours to remove oils, greases, waxes and other organic contaminants from the surface of components. It’s a non-aqueous process, making it ideal for cleaning parts that are sensitive to water or moisture before they undergo critical surface treatments, such as coating, plating or bonding.

Unlike mechanical or water-based cleaning methods, vapour degreasing delivers a completely residue-free finish. The process ensures that every surface (even those with complex geometries) is free from contamination, allowing for superior adhesion of subsequent coatings and improved long-term component performance.

How the vapour degreasing process works

At the heart of the process is a solvent, often perchloroethylene (perc), which is heated in a sealed chamber until it vaporises. Modern vapour degreasers operate as closed-loop systems that recover, filter and recycle solvent continuously. This enhances both environmental control and process efficiency. The steps typically include:

- Boiling and vapour generation: The cleaning solvent is heated to produce vapour that rises into the chamber.

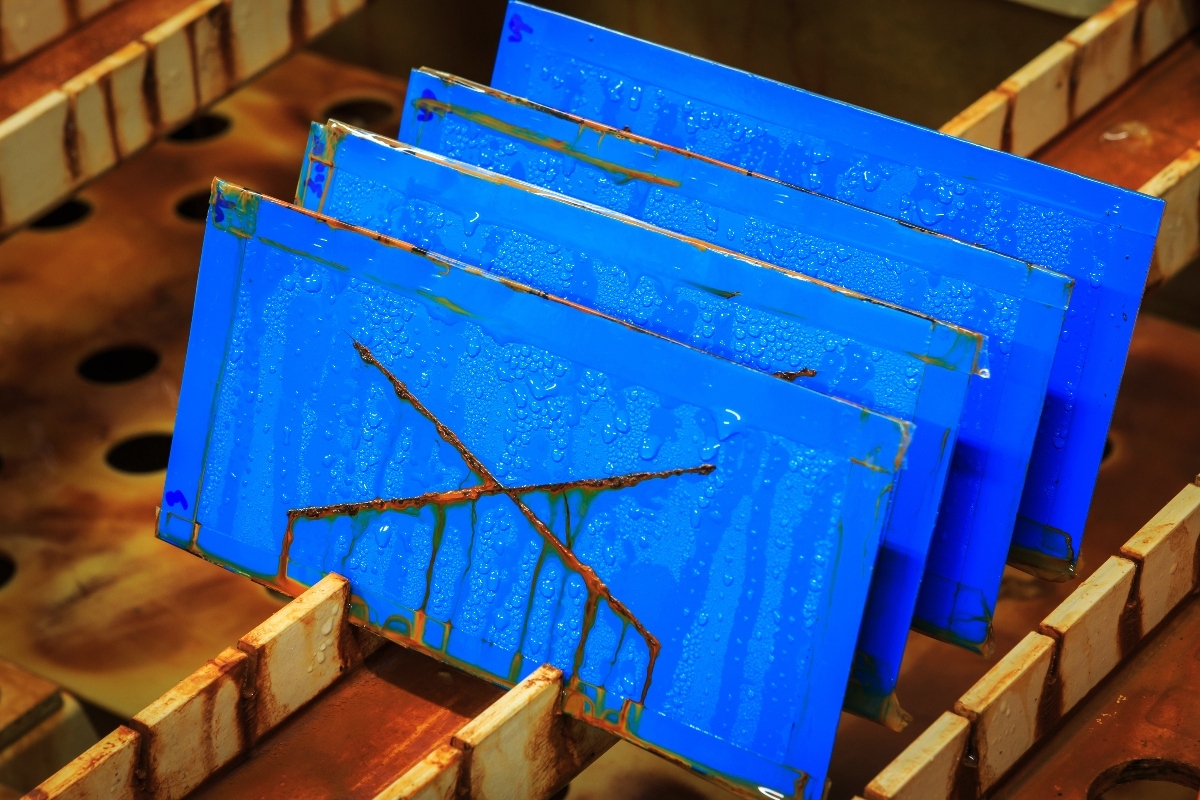

- Condensation on the component: Cooler components are suspended above the boiling solvent. As the hot vapour makes contact with their cooler surfaces, it condenses into liquid droplets. These droplets dissolve contaminants such as oil, grease and machining residues.

- Solvent draining: The solvent (carrying dissolved contaminants) runs off the component and back into the boiling sump where it is distilled and purified for reuse.

- Drying and recovery: Because the cleaning action relies on evaporation, the component emerges completely dry with no need for rinsing or forced drying.

Advantages of vapour degreasing

Vapour degreasing delivers a highly consistent and thorough clean, as the solvent vapour is pure at the point of contact with each component. This ensures identical results with every cycle and allows the vapour to penetrate complex shapes, fine threads and internal bores that other cleaning methods can’t effectively reach. By completely removing oils, greases and machining residues, it provides the clean foundation needed for reliable coating adhesion and long-term component performance.

Because the process uses solvent vapour rather than water, parts emerge completely dry and free from residues or corrosion risk. Modern closed-loop systems also recover and recycle the solvent, reducing waste and emissions while maintaining process efficiency. The result is a fast, repeatable and environmentally controlled method for achieving the highest standards of cleanliness in precision manufacturing.

Typical applications for vapour degreasing

Vapour degreasing is used wherever components demand absolute cleanliness before subsequent treatments or assembly. Its ability to handle delicate geometries and moisture-sensitive materials makes it a cornerstone of modern precision manufacturing. Common applications include:

- Aerospace: Cleaning precision actuator, valve and landing gear components before coating or assembly.

- Oil and gas: Removing machining oils from downhole tools, valves and pump parts before coating or inspection.

- Energy and power generation: Preparing turbine blades, shafts and seals for protective coatings.

- Defence and advanced engineering: Ensuring corrosion-free, contamination-free metal surfaces for critical components.

- Medical and optical industries: Cleaning components where even microscopic residues could impair performance.

Why vapour degreasing is still relevant today

Where new aqueous cleaning systems and ultrasonic methods have emerged, vapour degreasing remains unmatched in its ability to deliver a perfectly clean, dry surface especially for components with intricate internal features.

As industries move toward tighter tolerances, higher performance expectations and environmentally controlled processes, vapour degreasing continues to evolve. Modern systems employ solvent recovery, filtration and automation to improve safety, efficiency and compliance with environmental regulations such as REACH.

Flawless cleaning ready for flawless coatings

Vapour degreasing remains one of the most effective and reliable cleaning processes for precision-engineered components. Its ability to deliver a residue-free finish, reach internal geometries, and prepare surfaces for advanced coatings ensures it continues to be indispensable across industries.

At Hardide, vapour degreasing plays a critical role in achieving the superior adhesion and durability for which the company’s chemical vapour deposition (CVD) tungsten carbide coatings are known.

Hardide employs a dual cleaning approach, combining electrolytic alkaline cleaning with perchloroethylene vapour degreasing to remove even the most persistent machining residues and organic contaminants. Our advanced perc cleaning machine also uses a vacuum-sealed process volume which captures all solvent vapours and prevents emissions.

This process ensures that every component (no matter how intricate) is perfectly clean before coating, guaranteeing strong metallurgical bonding and uniform coating growth across internal and external surfaces.

For Hardide, vapour degreasing is a foundational aspect of coating performance. The result is consistently high coating adhesion, reliability under stress and long-term protection against wear, corrosion and erosion.