Among the many testing protocols used for corrosion across industry, ASTM B117 stands as the benchmark for evaluating a coating’s ability to protect metal substrates from corrosive attack.

For more than eight decades, it has been relied upon by engineers, manufacturers and regulatory bodies as the primary comparative test method for accelerated corrosion assessment.

This article outlines what ASTM B117 is, why compliance matters, how it is used across sectors as the most recognised indicator of coating durability.

What is ASTM B117?

ASTM B117, formally titled Standard Practice for Operating Salt Spray (Fog) Apparatus, defines the method for conducting a standardised salt spray (salt fog) corrosion test.

In this controlled laboratory environment, test specimens are exposed to a continuous fine mist of saline solution (typically 5% sodium chloride) at an elevated temperature of 35°C. The purpose is to accelerate corrosion mechanisms that would otherwise occur over long periods in natural conditions.

Rather than predicting exact in-service lifespan, ASTM B117 provides a repeatable and comparative measure of corrosion resistance between materials, coatings or process treatments.

Why is ASTM B117 so widely used?

ASTM B117 has earned its position as the industry’s most recognised corrosion test because it delivers consistent, comparable and actionable results across a wide range of applications. Its long-standing reputation is built on several key advantages that make it indispensable for engineers and manufacturers alike.

Repeatable, standardised results

Because the method tightly controls parameters such as temperature, solution composition and spray rate, results from different laboratories can be reliably compared. This gives engineers and procurement teams confidence when benchmarking one coating system against another.

Accelerated corrosion exposure

The test significantly compresses corrosion timeframes. What may take months or years in real environments can be observed in mere hours or days, enabling faster qualification of coatings or material systems.

Cross-industry acceptance

Aerospace, energy, oil & gas, automotive, defence and general manufacturing all use ASTM B117 as their baseline corrosion-resistance test. As such, it has become the default requirement in supplier specifications, coating datasheets and quality control protocols.

Foundation for further testing

Many more advanced or application-specific corrosion tests are built from the principles of ASTM B117. Its longevity and global adoption make it the starting point for corrosion qualification programmes.

The compliance importance of ASTM B117

For manufacturers and coating suppliers, demonstrating strong performance in ASTM B117 testing is often essential for meeting OEM qualification requirements and achieving regulatory or industry compliance. On top of this, it is also integral to securing approval for use in safety-critical components and differentiating products based on verified corrosion protection.

Failing to meet required test hours or showing premature failure within the salt fog environment can disqualify a coating from consideration in high-value applications, especially where safety, reliability or environmental exposure are critical.

Increasing regulatory scrutiny (particularly around environmentally hazardous legacy coatings) makes ASTM B117 data even more important as organisations transition to more sustainable alternatives.

What ASTM B117 measures

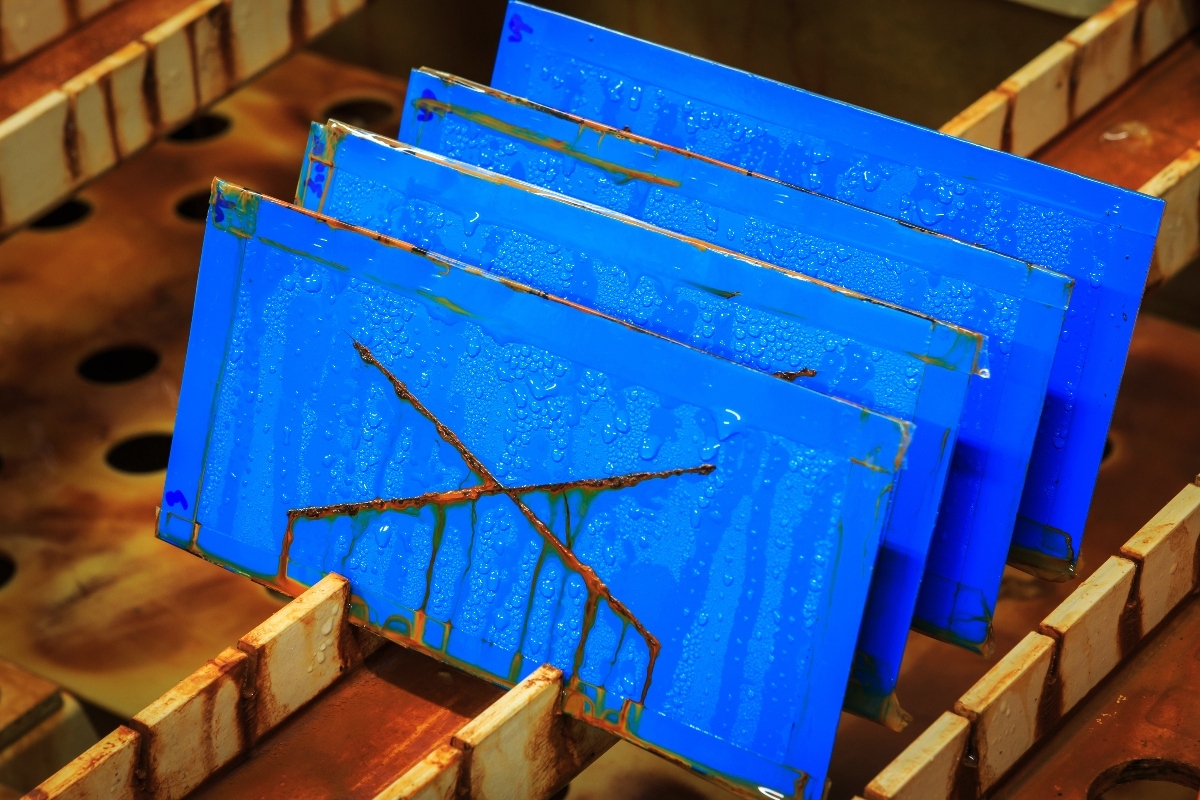

The test evaluates visible signs of corrosion on coated or uncoated metal substrates, including:

- Red rust on ferrous metals

- White corrosion products on zinc-based coatings

- Blistering, cracking, flaking or delamination of the coating

- Substrate attack in pores, cracks or defects

The duration a specimen withstands the environment without showing detrimental corrosion is a key comparative metric. Coatings with uniform, pore-free structures typically demonstrate superior performance, while coatings containing micro-cracks or porosity tend to fail earlier as corrosive agents penetrate these pathways.

This is why ASTM B117 is particularly effective for distinguishing between different hard coatings, surface treatments and barrier technologies.

The necessary role of salt spray testing for coating technologies

Modern engineering environments (from offshore to aerospace) demand coatings that can maintain their integrity under continuous exposure to moisture, saline solutions and corrosive chemicals. ASTM B117 is trusted precisely because it identifies weaknesses in coating structure, vulnerabilities caused by porosity or micro-cracking and reduced corrosion barrier performance over time.

Suppliers who consistently achieve high salt spray hours demonstrate technological maturity and reliability, boosting confidence in their coatings’ real-world resilience.

A trusted partner that complies with and exceeds ASTM standards

ASTM B117 remains the dominant standard for assessing corrosion resistance because it provides a consistent, accelerated and widely trusted method for comparing coating performance. Its ability to expose weaknesses in coating structure, porosity and adhesion makes it invaluable for engineers seeking reliable data when selecting protective solutions.

Hardide’s advanced tungsten carbide/tungsten metal matrix composite CVD coatings have repeatedly shown outstanding results in ASTM B117 testing, significantly outperforming legacy coatings such as hard chrome and HVOF. Their dense, pore-free structure offers an exceptional corrosion barrier, even under prolonged salt fog exposure, and ensures long-term protection in aggressive service conditions. Hardide also provides its own in-house salt spray testing services, giving customers reliable, application-specific data to support qualification and compliance programmes.

To explore corrosion challenges in more depth and learn how to improve component longevity, download our comprehensive Engineer’s Guide to Corrosion below.