Our customer, one of the largest independent directional drilling companies in the USA, was experiencing high wear on an internal surface in a mechanical assembly on one of its new measurement-while-drilling (MWD) tools. Due to the repeated travel of the internal parts of the cylinder, the component was experiencing wear on the cylinder ID. In addition, the tool had to withstand constant vibration and high shock impacts.

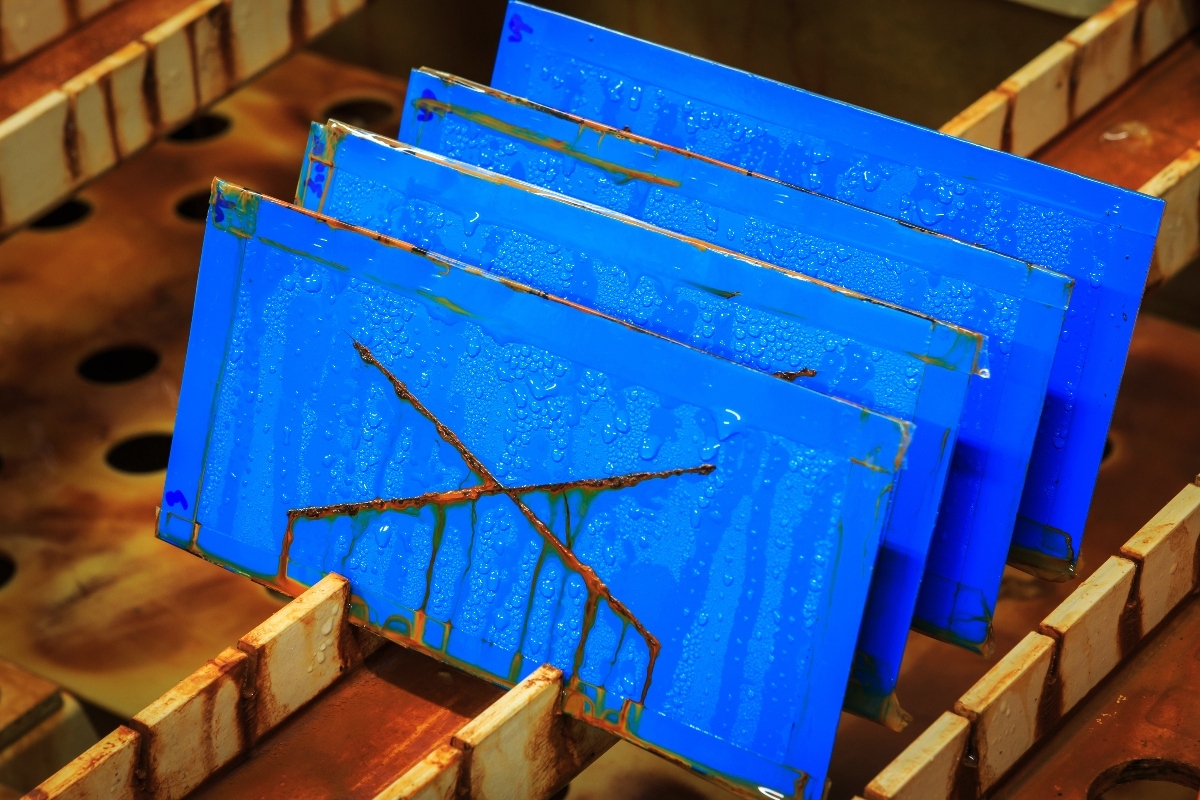

Before testing Hardide-T, our nanostructured tungsten carbide/tungsten metal matrix CVD coating, the customer tried ceramic components as well as metal parts with different forms of nitriding, including QPQ. These were not successful and resulted in little-to-no wear resistance and with corrosion visible in one case.

Our new case study details how Hardide-T solved the problem and that our customer reports large cost savings and significant life extension of the previously failing part.