In high-performance engineering, wear is one of the most common and costly challenges. Among the various wear mechanisms, adhesive wear is particularly significant due to its impact on component reliability and lifetime.

In order to prolong component life and minimise maintenance costs, engineers need to understand what adhesive wear is, where and why it occurs, the risks it poses and the practical solutions available to mitigate it.

What is adhesive wear?

Adhesive wear is a type of material damage that occurs when two solid surfaces slide against each other under load, causing fragments of material to transfer from one surface to another. At the microscopic level, high contact pressure causes asperities (surface roughness peaks) to weld together momentarily due to localised heat and plastic deformation. When the surfaces move, these micro-welds break, tearing tiny particles away. Over time, this process can produce significant material loss, surface roughening and debris, all of which degrade performance.

Two additional phenomena related to adhesive wear are also worth noting.

- Sliding wear is the broader term for wear caused by relative motion. Adhesive wear is a major contributor to sliding wear in metal contacts.

- Galling is an extreme form of adhesive wear where the material transfer is so severe that it results in rapid surface roughening and can cause components to seize altogether. Galling often occurs under high loads and low-speed conditions, such as threaded fasteners, valve stems and mechanical joints without proper lubrication.

Where and why does adhesive wear occur?

Adhesive wear is common in components that experience sliding contact under high loads and insufficient lubrication. This can take place in a number of applications.

- Hydraulic actuator pistons and rods

- Shafts running in plain bearings

- Valves and pumps handling abrasive fluids

- Aircraft landing gear and actuation systems

- Fasteners and threaded parts subjected to repeated tightening

Certain material combinations are also more prone to adhesive wear, such as when two similar metals rub together. In contrast, using dissimilar materials often reduces the tendency for adhesive bonding.

Risks and costs of adhesive wear

Unchecked adhesive wear can lead to mechanical challenges like premature component failure, loss of dimensional accuracy and/or increased friction and energy consumption. In safety-critical applications like aerospace actuators or oil and gas downhole tools, adhesive wear can compromise operational integrity, resulting in costly repairs or hazardous incidents. The increased maintenance costs and unscheduled downtime can easily become unmanageable.

Solutions to prevent adhesive wear

Reducing adhesive wear requires addressing the underlying conditions that cause it.

Material pairing

Using dissimilar material pairs reduces the chance of micro-welding. For example, pairing stainless steel with a hard ceramic or carbide layer can be effective.

Lubrication

Maintaining an appropriate lubricating film is essential to prevent direct metal-to-metal contact. Proper lubricant selection and ensuring seals and lubricators work reliably are critical.

Design considerations

Designing for minimal sliding or optimising the load distribution helps reduce high contact pressures that promote micro-welding. This may involve precision surface finishes, tighter tolerances or redesigning contact interfaces.

Surface treatments and hard coatings

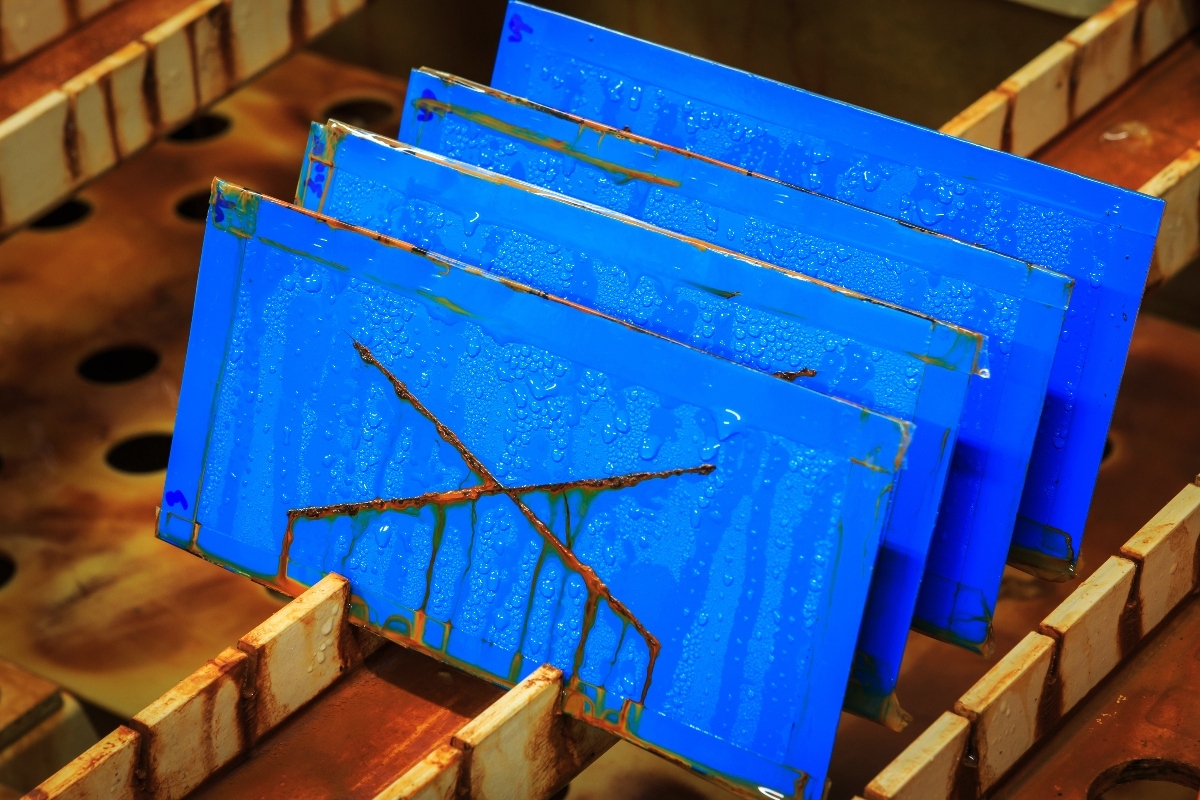

One of the most effective strategies is to apply a hard, low-friction, and non-porous coating to the component surface. High-performance coatings act as a barrier to welding and tearing mechanisms by providing high hardness (resisting micro-cutting and deformation), a smooth and polishable finish (maintaining a stable contact surface for seals and lubricants), chemical inertness (resisting corrosion which can exacerbate wear) and excellent toughness (withstanding impact and shock loads without cracking).

A key example of one of these coatings include advanced chemical vapour deposition (CVD) tungsten carbide coatings, which form a dense, pore-free protective layer that bonds metallurgically to the substrate and withstands adhesive wear, galling and corrosion.

Protect from adhesive wear and minimise maintenance costs

Adhesive wear, along with sliding wear and galling, poses serious risks to the performance and lifespan of critical components. Whilst smart material selection, effective lubrication and careful design all help to manage this issue, protective coatings remain one of the most practical and effective solutions.

Hardide’s advanced CVD tungsten carbide coatings provide a proven barrier against adhesive wear, combining high hardness, excellent toughness and a smooth, seal-friendly finish that stands up to wear, galling and corrosion even in the harshest environments. By protecting vital metal surfaces, we help customers across industries extend component life and reduce downtime.

To learn more about how to prevent adhesive wear and choose the right coating for your application, download our practical guide below.