In industrial environments where components are exposed to friction, impact and particulate matter, abrasion is one of the primary causes of wear and premature failure. Abrasion resistant coatings are therefore essential to maintaining equipment reliability and extending service life. These coatings provide a hard, protective layer that resists mechanical wear caused by contact with solid particles, fluids or other surfaces.

In order to choose the right coating to maximise component life, engineers need a clear understanding of the available coatings in context with abrasive environments.

What makes a coating abrasion resistant?

The abrasion resistance of a coating depends on several interconnected properties:

- Hardness: The ability to resist scratching, cutting or ploughing by abrasive materials. High hardness prevents micro-cutting and deformation of the surface.

- Toughness: A measure of a coating’s ability to absorb energy and deform without cracking. Brittle coatings may fracture under impact or stress.

- Adhesion: Strong metallurgical bonding between coating and substrate ensures durability under high loads.

- Porosity: Pore-free coatings provide a continuous barrier against wear and corrosion. Porosity can weaken a coating and allow abrasive ingress.

- Uniformity: Consistent coating thickness ensures even load-bearing and predictable wear performance.

The optimal abrasion resistant coating combines hardness and toughness, which is a synergy that allows it to resist both micro-cutting wear and fatigue cracking. This is particularly important for applications where abrasion occurs alongside impact or erosion.

Common types of abrasion resistant coatings

When selecting an abrasion resistant coating, engineers have traditionally turned to hard chrome plating or thermal spray coatings such as HVOF. Both offer surface hardness and wear protection, but each has limitations that restrict performance, design flexibility and sustainability.

Hard Chrome Plating (HCP)

Hard chrome has been a mainstay for protecting steel parts against wear and friction, offering decent hardness and a bright finish. However, its environmental impact and mechanical limitations make it increasingly unfit for modern engineering applications.

- Cracked and porous layer allows corrosion and wear to penetrate.

- Fatigue debit up to 40% due to tensile stress and hydrogen embrittlement.

- Uneven build-up on edges, requiring costly grinding.

- Hexavalent chromium use makes it heavily restricted under REACH and OSHA.

High Velocity Oxy-Fuel (HVOF) Coatings

HVOF coatings use tungsten carbide particles in a cobalt or chrome binder to produce a hard, wear-resistant surface. They offer solid abrasion protection but face geometric and durability limitations, particularly in corrosive or impact environments.

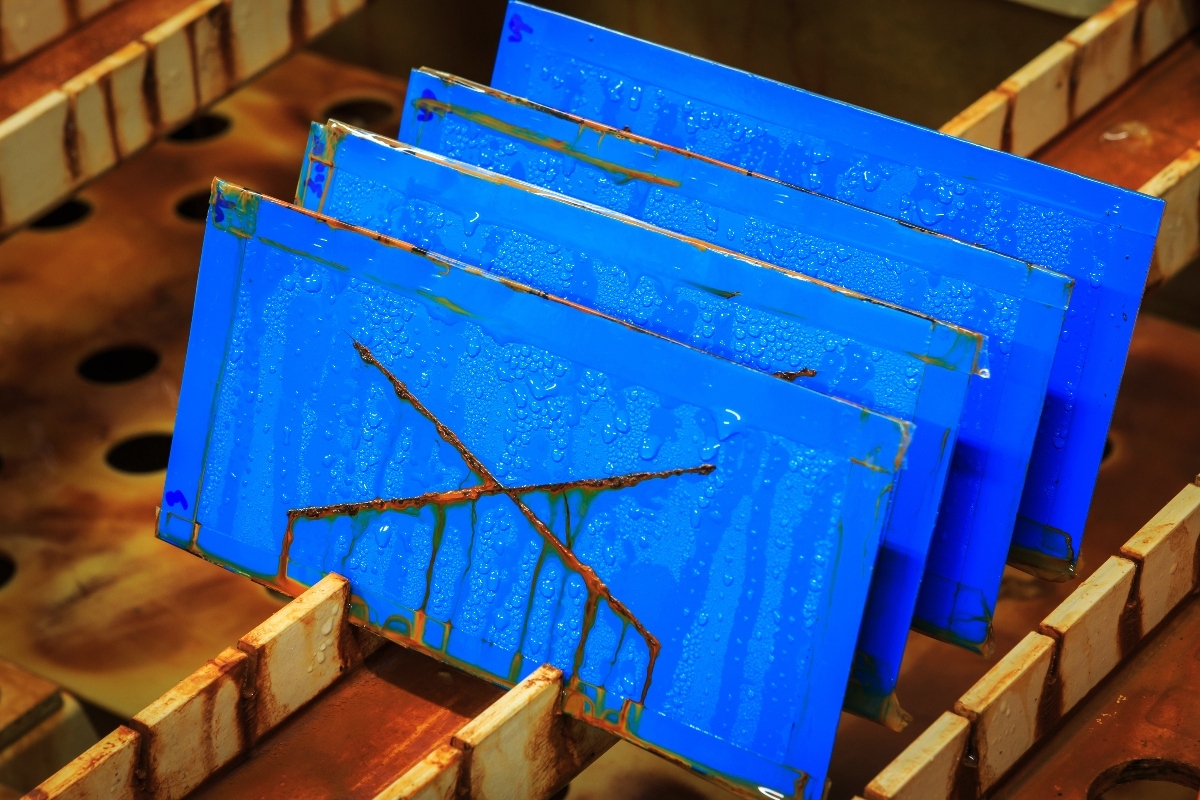

- Porosity and binder wear lead to rough “cheese-grater” surfaces over time.

- Line-of-sight process unsuitable for internals or complex shapes.

- Rough as-sprayed finish demands post-grinding.

- Residual stresses can cause cracking or delamination.

Why toughness and porosity matter

Hardness alone does not guarantee durability. Toughness allows coatings to absorb impact and resist cracking vital for parts subject to vibration or shock loads such as turbine blades, downhole tools and pump rotors.

Equally, porosity determines the coating’s ability to resist corrosion and abrasive ingress.

Pore-free coatings complete barriers against aggressive media, acids and hydrogen, preventing substrate corrosion even under abrasive wear.

CVD as the superior choice for abrasion resistant coatings

CVD coatings are formed atom-by-atom from a gas phase, producing a dense, uniform and metallurgically bonded layer. They combine extreme hardness with toughness, giving long-lasting protection against abrasion, but also erosion and corrosion too. Tungsten carbide CVD coatings (such as Hardide) provide further resistance by combining high hardness (up to 1600 HV) with ductility and a pore-free structure. Unlike HVOF or hard chrome, the CVD process allows uniform coating on internal and complex shapes, making it suitable for valves, pumps, downhole tools and actuators.

- Pore-free and crack-free for total surface protection.

- Uniform coverage on internal and complex geometries.

- High hardness (up to 1600 HV) with excellent toughness.

- No binders or toxic materials, fully REACH-compliant.

The coating of choice across industry

Abrasion resistant coatings are essential to modern industry, protecting components from wear and extending service life in the harshest conditions. Whilst traditional methods such as hard chrome and HVOF remain common, they are increasingly being replaced by advanced, sustainable technologies.

CVD tungsten carbide coatings developed by Hardide offer the optimal balance of hardness, toughness, and chemical resistance. Their ability to coat complex geometries uniformly and provide pore-free protection positions them as the leading solution for high-performance abrasion resistance across aerospace, energy, and manufacturing sectors.

For a deeper understanding of the mechanisms that cause component wear and how to prevent them, download our full guide below.