Corrosion fatigue is often an underestimated threat to the longevity of critical components across industries such as aerospace, oil and gas, power generation and advanced manufacturing. It combines two of the most destructive forces in engineering, cyclic stress and corrosive environments, to significantly accelerate component failure. This leads to increased downtime and drives up maintenance frequency and replacement costs.

Understanding the mechanics behind corrosion fatigue and how to mitigate its effects is essential for engineers, maintenance managers and designers aiming to extend equipment lifespan and reduce total cost of ownership.

What is corrosion fatigue?

Corrosion fatigue refers to the progressive and localised structural damage that occurs when a material is subjected to cyclic loading in a corrosive environment. Where mechanical fatigue alone causes cracking due to repeated stress cycles, corrosion fatigue is intensified by the chemical degradation of the material, which accelerates crack initiation and growth.

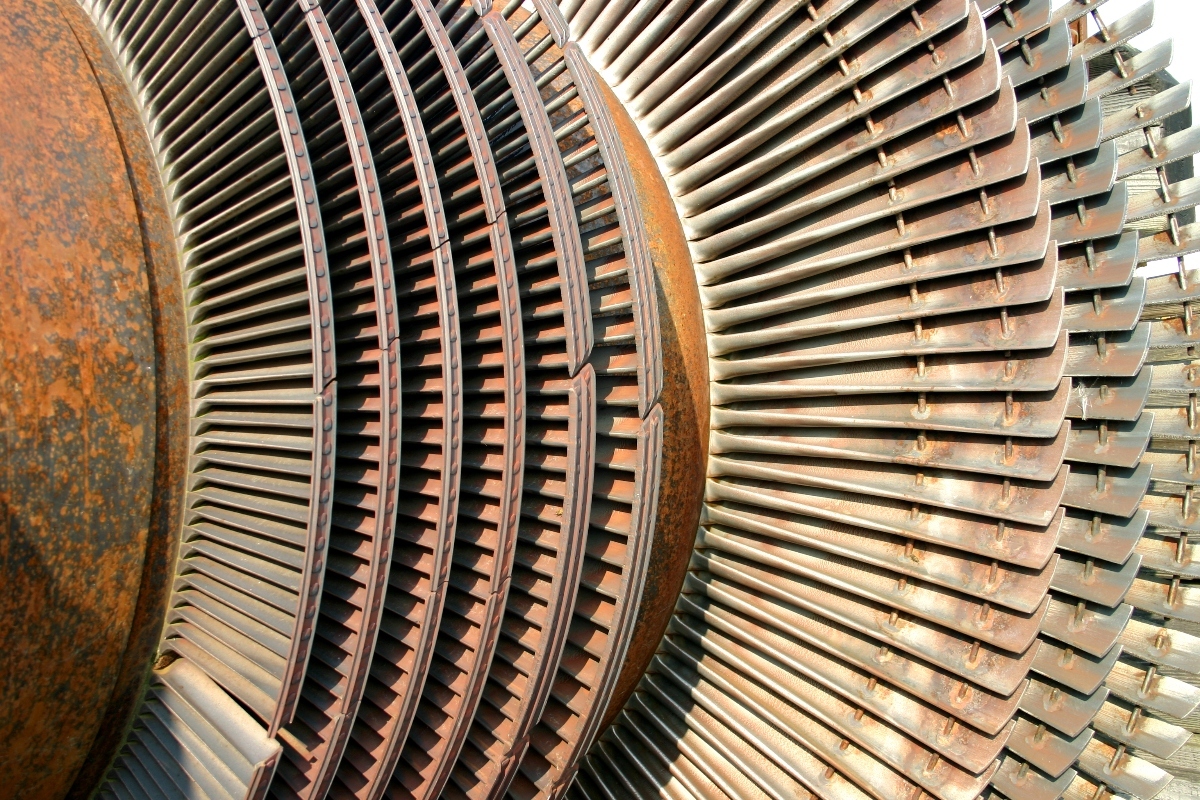

Corrosion fatigue does not require particularly aggressive chemicals to take effect. Even moisture, salt-laden air or acidic environments can trigger it under cyclic stress. Components such as actuator rods, valve stems, turbine blades and rotating shafts are particularly vulnerable, which is only intensified when they operate in humid or chemically aggressive conditions.

Why you should be taking the right precautions

The effects of corrosion fatigue go beyond that of eventual component failure. They cascade into increased inspection frequencies, unscheduled shutdowns, emergency repairs and ultimately premature replacement. For critical assets such as pumps or turbine components, this can lead to significant operational disruption and financial losses.

In industries like aerospace and energy, where safety and uptime are paramount, even a minor crack caused by corrosion fatigue can ground aircraft for maintenance or halt production.

Why traditional metal coatings fall short when it comes to corrosion fatigue

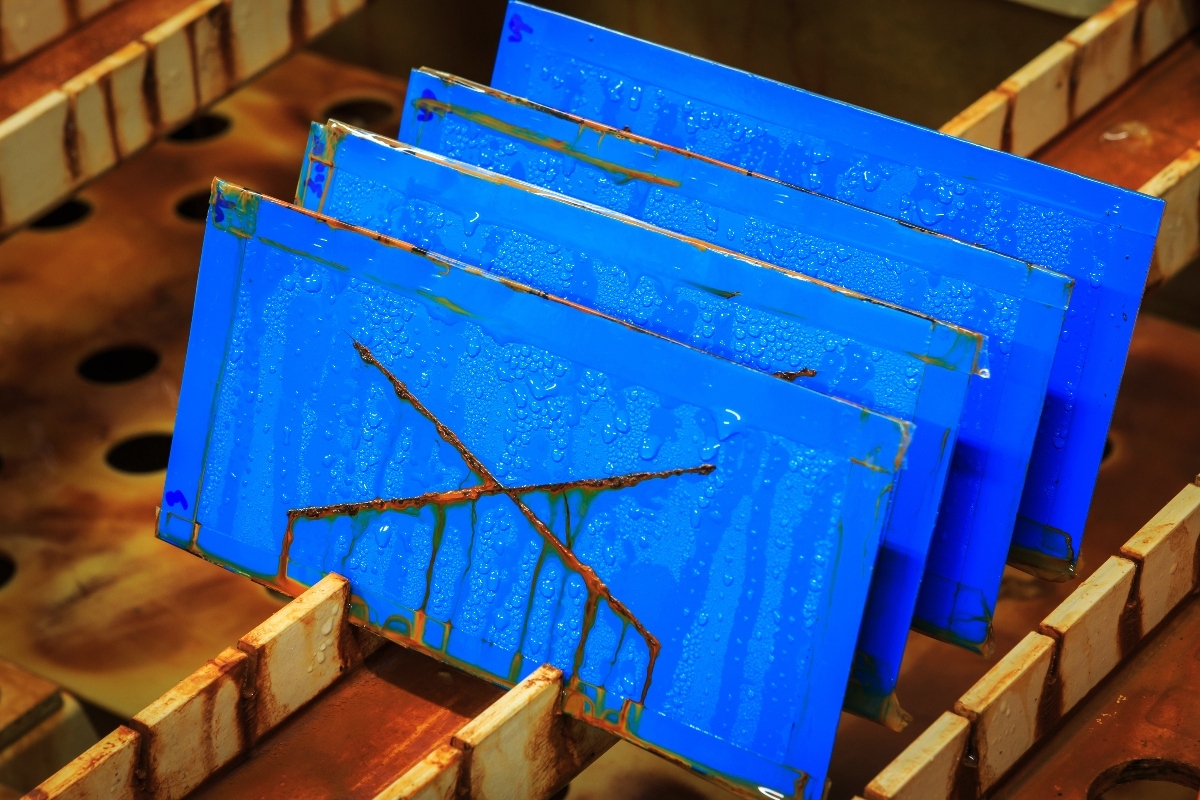

Many traditional protective coatings, such as Hard Chrome Plating (HCP) or thermal spray (HVOF), provide only partial protection against corrosion fatigue. These coatings often suffer from micro-cracks or porosity, which act as pathways for corrosive agents to reach the substrate. Under cyclic stress, these imperfections become stress concentrators, accelerating crack propagation leading to coating delamination or substrate failure.

On top of this. The brittle nature of some coatings and their poor ability to deform with the substrate under load can contribute to cracking under fatigue conditions. Even when protective initially, these coatings may degrade in performance over time and ironically become contributors to failure rather than a defence against it.

Advanced CVD coatings - a proven preventative solution

Advanced Chemical Vapour Deposition (CVD) coatings offer a step-change in corrosion fatigue resistance. These coatings are deposited atom-by-atom from the gas phase, providing a pore-free barrier metallurgically bonded to the substrate. This means that it can uniformly cover complex geometry components. Unlike conventional coatings, CVD coatings are:

- Pore-free and crack-free as-deposited, providing a continuous barrier to corrosive agents

- Strongly metallurgically bonded to the substrate, eliminating delamination under stress

- Resistant to mechanical fatigue, with minimal or even positive fatigue debit (between -10% and +10%)

- Tough yet ductile, allowing them to withstand deformation and shock loads without failure

This unique combination of high hardness, exceptional toughness and structural integrity under cyclic load makes advanced CVD coatings an ideal solution for mitigating corrosion fatigue. In fact, the nano-structured composition of Hardide’s tungsten carbide coatings enables components to resist wear, corrosion and fatigue simultaneously. This is a rare and powerful combination in demanding industrial settings.

Design for longevity with leading protective performance

Corrosion fatigue remains one of the most insidious failure mechanisms in critical components, but it is manageable. As industries face increasing pressure to extend equipment life and reduce costs, the choice of surface coating becomes more vital than ever.

Hardide’s CVD tungsten carbide coatings offer a robust and proven solution, one that maintains fatigue resistance under cyclic stress and resists corrosive attack even in the harshest environments. By investing in advanced coatings, engineers can effectively design for longevity and reliability and significantly reduce the hidden costs of corrosion fatigue.

For a deeper understanding of the mechanisms that affect component life, download our full guide on design for longevity below.