Bearings are a major component in countless machines from aircraft engines to industrial pumps. Yet, despite their critical role in reducing friction and supporting loads, bearings are particularly prone to wear that can lead to costly failures/maintenance and reduced operational efficiency. Because of this, engineers need a clear understanding of how to prevent bearing wear to maximise the lifespan of components and maintain reliability.

What is bearing wear and why is it important?

Bearing wear occurs when friction, contamination or improper operation causes gradual removal or damage of the bearing material. This usually manifests as either abrasive wear (caused by hard particles like dust, sand or metal debris), adhesive wear/galling (resulting from metal-to-metal contact when lubrication fails), corrosive wear (initiated by chemical reactions or exposure to moisture and corrosive fluids) or fatigue wear (surface cracking due to repeated load cycles leading to spalling)

Even minor wear can escalate into significant problems when it comes to bearings, such as vibration that introduces instability and dampened precision, heat generation (with the potential risk of deformation), efficiency losses and eventually failure. In sectors like aerospace, energy or heavy manufacturing, the consequences can be both operationally and financially severe.

Key strategies to minimise bearing wear

Proactive preventative measures are essential when it comes to maximising the lifespan of bearings to avoid the aforementioned problems and minimise the need for costly maintenance. By combining proper practices with advanced protective technologies, it is possible to significantly reduce wear and extend component service life.

Proper lubrication

Lubrication creates a film that separates bearing surfaces, reducing friction and preventing metal-to-metal contact. Using the correct lubricant for your operating environment (e.g., high-temperature, high-load or corrosive conditions) is a necessity when it comes to bearings, and maintaining lubrication intervals is critical for a lot of machinery.

Contamination control

Dust, sand or metallic debris are the leading causes of abrasive wear. This highlights the importance of installing effective seals and filtration systems to prevent these contaminants getting into contact with bearings. You should also regularly inspect and clean their housings regularly to prevent ingress of contaminants.

Correct installation and alignment

Misalignment causes uneven load distribution, accelerating wear. To prevent this you should ensure proper fit tolerances and use alignment tools during installation, and make sure to avoid over-tightening which can introduce internal stress.

Load and speed management

Operating beyond design load or speed significantly increases fatigue wear. Engineers should review machinery duty cycles and ensure bearings are specified appropriately. For example, shock-absorbing components in high-vibration environments might be necessary.

Corrosion and chemical protection

Exposure to moisture or corrosive chemicals can compromise bearing surfaces. Apply protective coatings or use corrosion-resistant bearing materials and ensure proper environmental sealing in harsh conditions.

Advanced coating solutions for optimal bearing protection

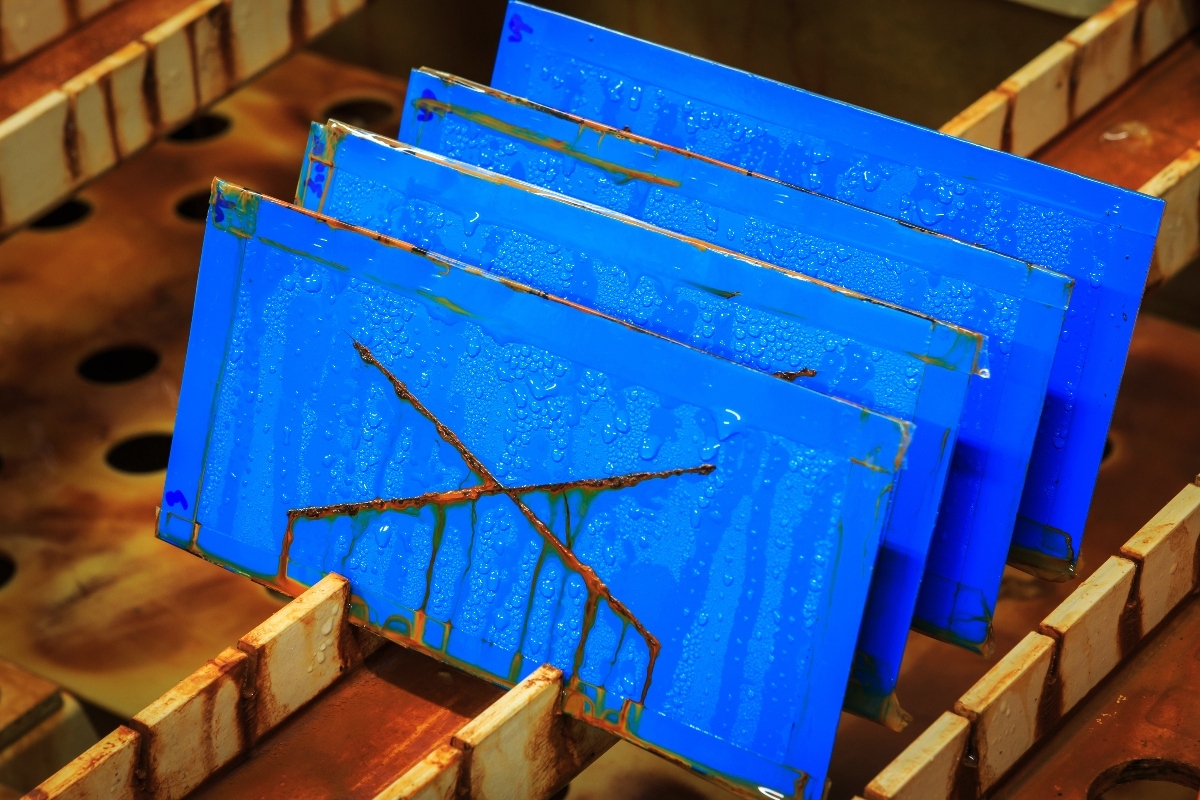

These above practices can help reduce wear, but applying advanced surface coatings to bearings or their mating components can dramatically extend service life in comparison. Traditional options like hard chrome plating and HVOF thermal spray have been widely used, but they present certain limitations.

- Micro-cracks and porosity can allow corrosion ingress.

- Cobalt binder in HVOF WC coatings can leach, creating “cheese-grater”

- surfaces that accelerate seal and bearing wear.

- Limited ability to coat complex geometries or internal bearing surfaces.

To avoid these issues, there is an increasing focus on coating solutions that provide uniform coverage, high hardness combined with toughness and a pore-free barrier to protect against wear. This is particularly the case for bearings, as selecting the right coating for the can significantly reduce unplanned maintenance, lower total lifecycle costs and extend bearing life well beyond that achievable with lubrication and alignment practices alone. Fortunately, recent CVD coatings have proven to provide these features and more as a perfect replacement for hard chrome and HVOF.

The ultimate protection for bearings to maximise life

Preventing bearing wear is key to improving reliability and reducing downtime. Combining factors like good lubrication and contamination control can help, but utilising advanced surface engineering through coating is easily the most effective way to extend service life.

For the most demanding conditions, Hardide’s CVD tungsten carbide coatings provide exceptional wear, corrosion and galling resistance. Their pore-free, tough and hard surface keeps bearings and mating components performing longer, cutting maintenance and replacement costs. All in all, it’s the perfect choice for bearing components.

To learn more about maximising component life, explore our guide to designing for longevity, which covers best practices in materials, coatings and surface engineering for extended service performance.