Related Resources

Pump corrosion - causes, types and solutions

Understanding how corrosion initiates and propagates within pump systems is essential for controlling long-term reliability and maintenance costs.

What is electrolytic alkaline cleaning?

Electrolytic alkaline cleaning is a specialised surface treatment process designed to remove contaminants from metal components using an electrically charged alkaline solution.

Vapour degreasing explained - process, applications and benefits

Vapour degreasing is a precision cleaning method that uses solvent vapours to remove oils, greases, waxes and other organic contaminants from the surface of components. Find out more about this crucial process.

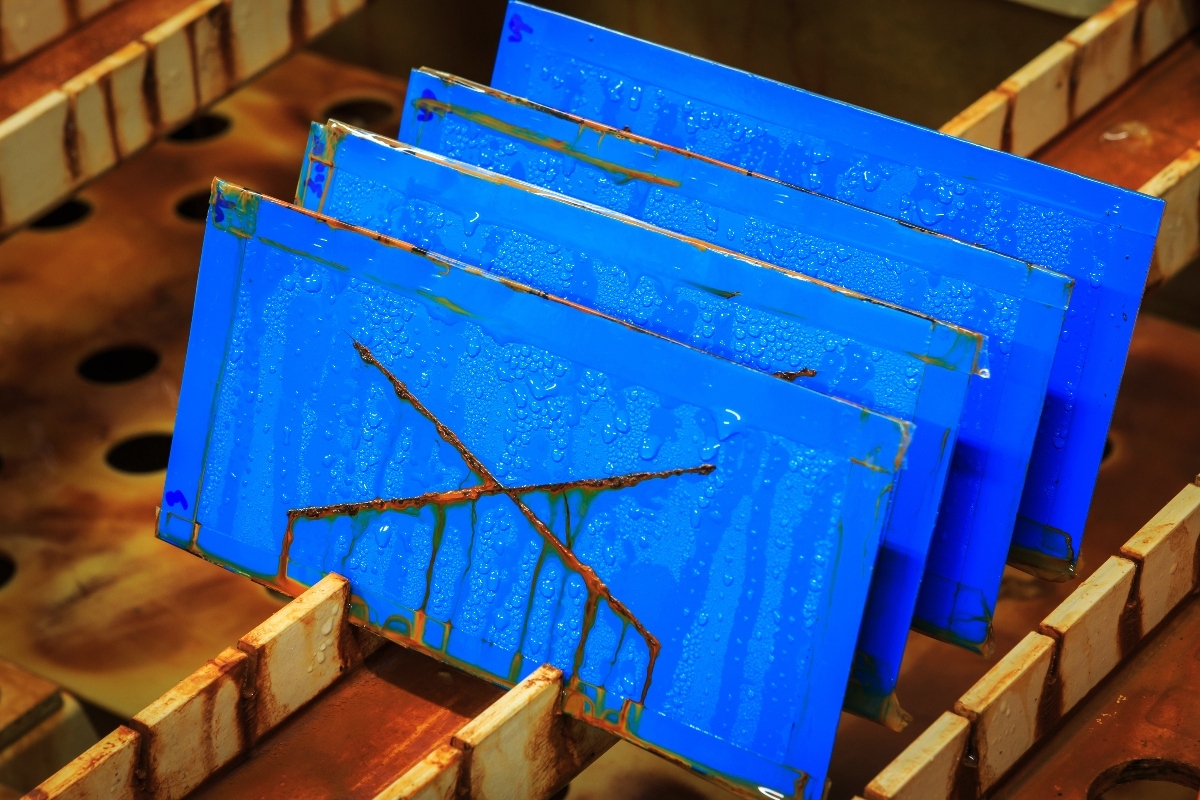

What is the ASTM B117 salt spray standard?

This article outlines what ASTM B117 is, why compliance matters, how it is used across sectors as the most recognised indicator of coating durability.

NACE standards - a guide to corrosion compliance

The series of standards developed by NACE International provide a rigorous framework to manage corrosion risk