Sand screen erosion is a prevalent industry-wide problem costing billions of dollars in facilities maintenance, well interventions, side-tracks and curtailed production. Statistical sand screen failure rates of high-rate producing wells with fines production indicate that 25% of wells will experience screen failure over a 25-year life. Hardide-T Mesh is a tungsten/tungsten carbide CVD (chemical vapour deposition) coating and process developed specifically to provide surface protection for the individual wires which comprise multi-layer woven metal mesh including sand screens.

The patented CVD application process means the coating can be precision applied to all surfaces of mesh tubes with outside diameters from 1.5”- 6”. The minimum mesh micron rating size is 175 μm; excellent for new and remedial well sand screens, and challenging filtration applications.

Hardide-T Mesh can be applied in a range of thickness from 15 – 40 μm (0.0006”-0.0016”) depending on the design and function of the mesh. The minimum coating hardness for mesh is 1250 Hv (58 HRc).

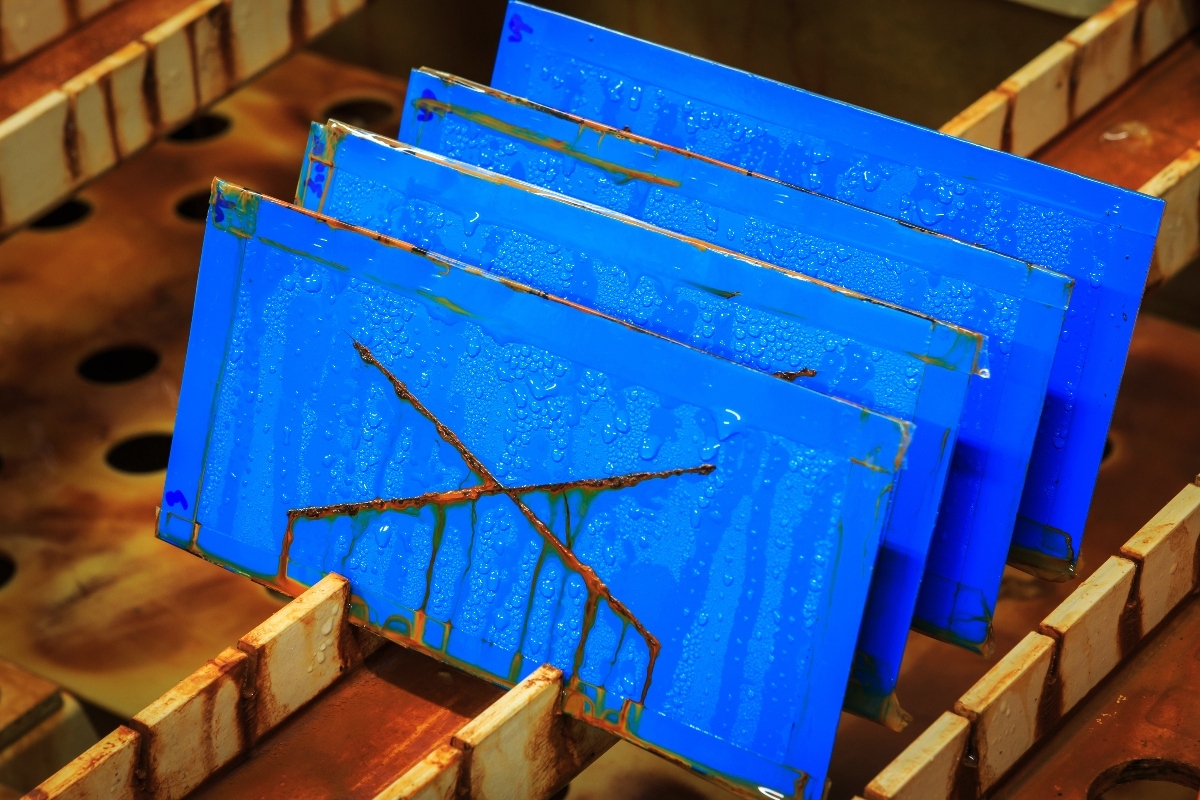

The coating has completed a rigorous test program including erosion testing, delamination testing, coating integrity testing, heat treat testing, and bend/burst/collapse testing.

Full details can be found in our Hardide-T Mesh Application Note on our website here.